From formwork design to manufacturing to on-site support, we have you covered, no matter where you are in the world.

Thanks to our extensive experience, our team of design engineers can resolve engineering complexities and simplify on-site operations with innovative designs that deliver high productivity and faster construction times – all without compromising on your building’s design vision or quality standards.

By using your architectural and structural drawings, we design a formwork system for your project with the most efficient construction process while optimising it for a long-term reuse on your future projects, saving you both time and cost in the long run.

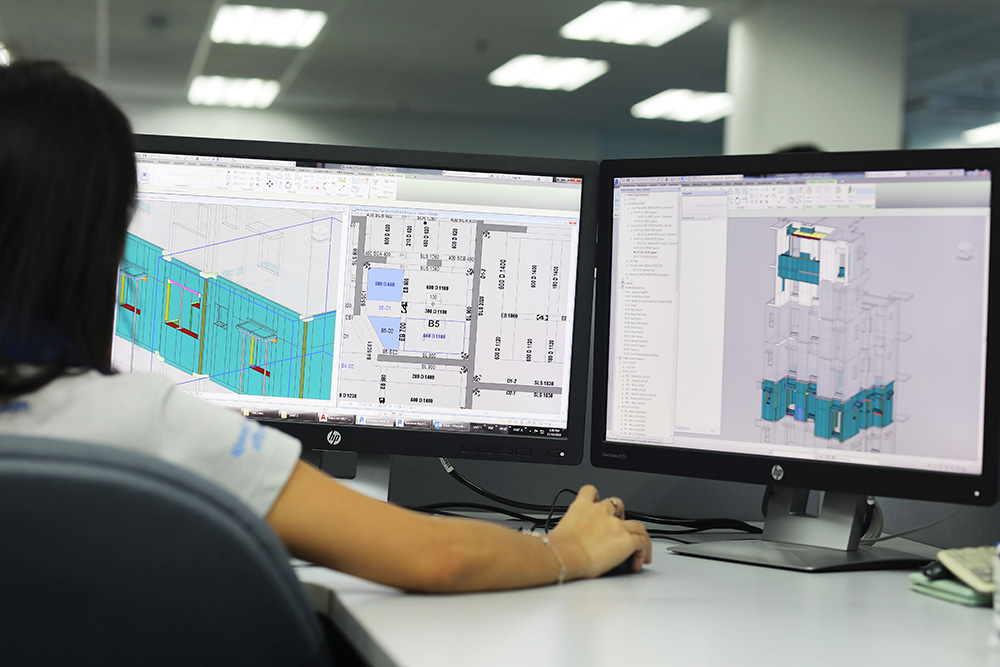

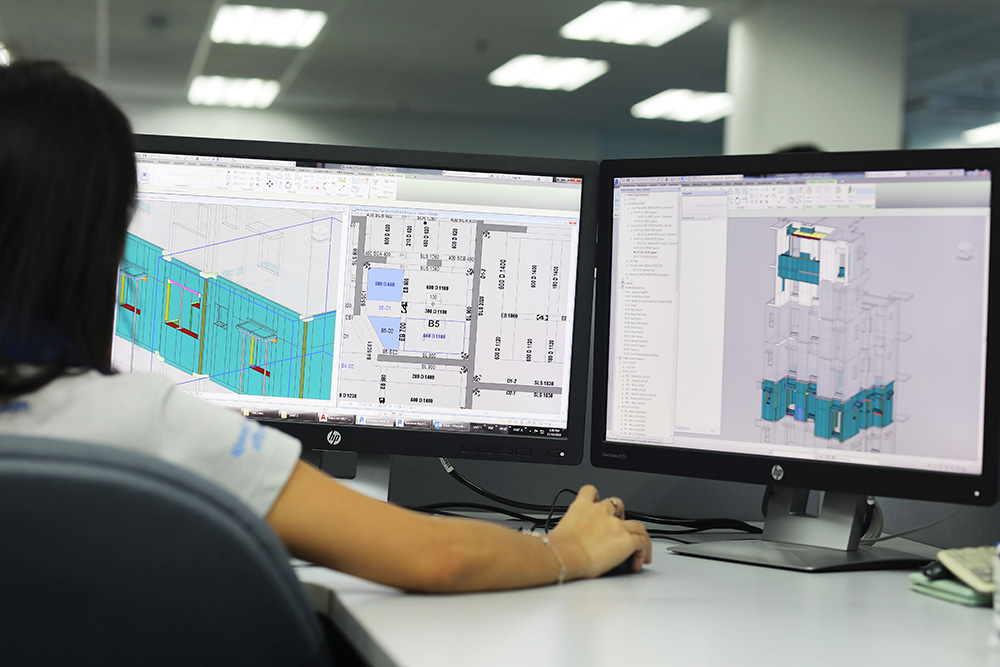

Our designers utilise the most advanced design tools, using 3D design software with our own in-house customised adaptations and plugins that were jointly developed with leading software providers. From simple layouts to complex structural designs, the MFE team is able to produce both elaborate 3D visualisations and simple-to-use designs for rapid construction work cycles and easy adoption by construction site teams.

Our state-of-the-art manufacturing centre in Port Klang, Malaysia uses the latest in production processes and technologies to produce the highest quality aluminium formwork panels for our customers. MFE’s formwork and safety products are manufactured to exact standards with multiple quality control points and quality assurance steps throughout our production processes.

In 2010, MFE integrated the ‘Friction Stir Welding’ system into our aluminium formwork panel manufacturing process. Friction Stir Welding minimises metal distortion during welding and produces the highest welding strength possible to extend the formwork’s durability and longevity. While this highly-advanced and eco-friendly welding system is used predominantly in the aerospace and automotive industries, MFE was the first formwork company in the world to develop and incorporate the technology into our processes.

With years of extensive experience on multiple types of construction projects under our belt, our technical and site support engineers will be able to assist and train your construction teams on how to use MFE’s formwork systems effectively, with a focus on productivity, end quality, and safety.

Our experts will guide your construction teams through the entire deployment process, from setup to completion, including:

While the on-site support duration may vary depending on the size and type of project, MFE’s support engineers are typically on-site for approximately 8 weeks for each project.